In stormwater treatment, two factors are crucial: reliability and efficiency. Particularly in stormwater tanks, technical systems must function under full load while remaining economical over the long term. Operators often face two well-known challenges:

1. Floating debris must be reliably retained during stormwater inflow.

2. After the event, the tank floor must be effectively cleaned.

Traditionally, two separate systems are used: a baffle wall to retain floating materials and a flush tank to clean the tank floor. But why think in separate components when a smart solution can do both?

One System – Two Functions: Technical Symbiosis in the Stormwater Tank

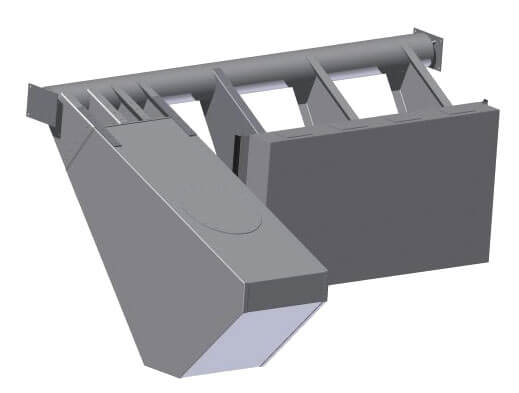

With years of experience in the outfitting of special structures and stormwater systems, SGS Aqua has developed a solution that intelligently combines both functions. The flush tank is designed and positioned to also serve as a baffle wall – a technically efficient dual purpose.

How it works:

The flush tanks are installed directly in front of the overflow. Their bodies act as a baffle wall, retaining floating materials during inflow. Custom closure elements seal the gaps between the tanks and the side walls – without impairing the flushing function.

Your Benefits at a Glance

•Space-saving: Perfect for retrofits and tight structures

•Cost-efficient: Fewer components mean lower material and installation costs

• Low-maintenance and durable

• Ideal for both new builds and upgrades

Conclusion: Compact, Smart, Reliable

This combined system is more than a clever construction – it’s a future-oriented solution for modern stormwater treatment. Whether you’re planning a new tank or upgrading an existing one: the combination of flush tank and baffle wall offers clear advantages in space, cost, and performance.

📩 Contact us to learn more – we’re happy to advise you.