Baffles are installed in a wide range of applications. They are most commonly used for floating material retention at spillways and spillway sills. Baffles retain floating matter due to their undercurrent function.

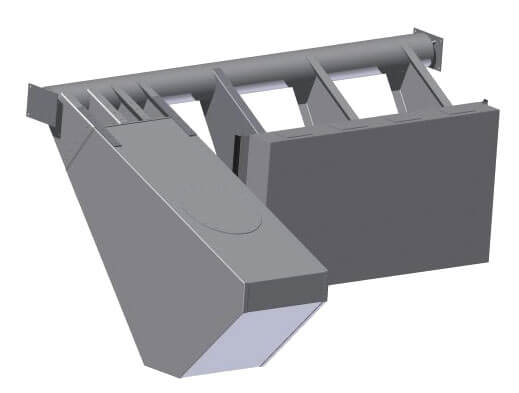

The conventional form of a baffle is a fixed baffle according to DIN 19558 with a distance from the discharge sill of 2 times the overfall height over the sill.

The disadvantage of fixed baffles in systems with highly fluctuating water levels is that floating matter accumulates in the area between the baffle and the discharge sill and enters the receiving water in the event of a discharge. This can be prevented by using movable, floating baffles. Both radial and vertical floating baffles are used as standard.

The proportion of pure floating matter in wastewater is usually low. Rather, a high proportion of suspended matter is contained in the wastewater. These substances cannot be retained by the use of baffles. Additional floating matter in mixed water from sealed surfaces is flushed into the sewer system, thus increasing the proportion of this floating matter in the mixed water.

Fixed baffles are made of stainless steel or GRP. Floating baffles are preferably made of GRP due to the material properties.